GRP pipe seals are critical components used in the construction and maintenance of pipelines in various industries such as water and wastewater management, chemical processing, oil and gas, and infrastructure projects. These seals are designed to provide a secure and watertight connection between GRP pipes and fittings, ensuring the integrity, longevity, and efficiency of the piping system. Here’s an extensive overview of GRP pipe seals:

- Material Composition: GRP pipe seals are typically made from high-quality elastomeric materials such as EPDM (Ethylene Propylene Diene Monomer) rubber, neoprene, or silicone. These materials are chosen for their excellent flexibility, resilience, chemical resistance, and durability, making them ideal for sealing applications in aggressive environments.

- Sealing Mechanism: GRP pipe seals function by creating a tight seal between the joint surfaces of GRP pipes and fittings. The elastomeric material compresses between the mating surfaces, forming a barrier against leaks, seepage, and water infiltration. This sealing mechanism ensures the integrity of the piping system and prevents costly leaks and repairs.

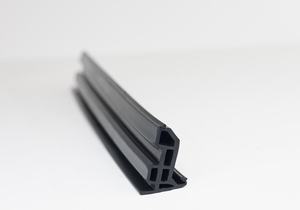

- Types of Seals: GRP pipe seals come in various types and configurations to accommodate different pipe diameters, joint configurations, and installation requirements. Common types include rubber gaskets, O-rings, compression seals, and flexible couplings. Each type is designed to provide specific sealing properties and ensure a reliable connection between GRP pipes and fittings.

- Rubber Gaskets: Rubber gaskets are commonly used in GRP piping systems to seal the joints between pipes and fittings. These gaskets feature a circular or rectangular profile with a hollow center that fits snugly around the pipe end. When compressed between the mating surfaces, rubber gaskets form a tight seal that prevents water leakage and ensures the integrity of the piping system.

- O-Rings: O-rings are circular elastomeric seals used to create a seal between two mating surfaces, such as pipe joints or fittings. Made from rubber or silicone, O-rings provide a reliable barrier against leaks and pressure loss, even under high-pressure conditions. They are available in various sizes and durometers to accommodate different pipe sizes and applications.

- Compression Seals: Compression seals are designed to seal expansion joints or gaps between GRP pipes, allowing for movement and thermal expansion without compromising the integrity of the piping system. These seals feature a flexible rubber or neoprene profile that compresses under pressure, creating a tight seal while accommodating pipe movement.

- Flexible Couplings: Flexible couplings are used to join two GRP pipes or fittings while allowing for misalignment, movement, and vibration. These couplings feature a flexible rubber sleeve or gasket with stainless steel bands or clamps that provide a secure and leak-proof connection. They are ideal for repairing damaged pipes or connecting pipes of different materials.

- Chemical Resistance: GRP pipe seals exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This chemical resistance ensures the longevity and reliability of the seals in corrosive environments such as chemical processing plants, wastewater treatment facilities, and industrial pipelines.

- Weather Resistance: GRP pipe seals are designed to withstand exposure to UV radiation, extreme temperatures, and weathering without degradation or loss of sealing performance. This weather resistance makes them suitable for both indoor and outdoor applications, including water distribution networks, sewage systems, and drainage infrastructure.

- Easy Installation and Maintenance: GRP pipe seals are designed for easy installation and require minimal maintenance to ensure long-term performance. They can be installed using compression fittings, adhesive bonding, or mechanical clamping, and periodic inspection and replacement are recommended to address wear and tear over time.

In summary, GRP pipe gaskets are essential components used to ensure leak-proof connections, prevent water infiltration, and maintain the integrity of GRP piping systems in various industries. With their durable construction, reliable sealing properties, and resistance to chemicals and environmental factors, GRP pipe seals contribute to the efficiency, longevity, and safety of pipelines and infrastructure projects around the world.