Concrete pipe seals are essential components used in the construction and maintenance of underground drainage and sewer systems, providing a reliable and durable solution for sealing joints between concrete pipes. These seals play a critical role in preventing water infiltration, soil erosion, and the ingress of debris into the pipeline, ensuring the integrity and efficiency of the overall drainage infrastructure. Here’s a comprehensive overview of concrete pipe seals:

- Material Composition: Concrete pipe seals are typically made from high-quality elastomeric materials such as EPDM (Ethylene Propylene Diene Monomer) rubber, neoprene, or natural rubber. These materials are selected for their excellent sealing properties, durability, and resistance to environmental factors.

- Sealing Mechanism: Concrete pipe seals function by creating a watertight seal between adjacent concrete pipes. The elastomeric material compresses between the pipe joints under pressure, forming a tight seal that prevents water infiltration and leakage.

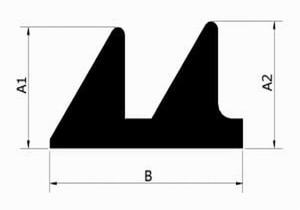

- Profile and Design: Concrete pipe seals are available in various profiles and designs to accommodate different pipe diameters, joint configurations, and installation requirements. Common profiles include O-ring seals, gaskets, and profiled seals designed to match the specific geometry of concrete pipe joints.

- Compression and Expansion: Concrete pipe seals are engineered to withstand compression and expansion forces exerted on the pipeline due to ground movement, temperature fluctuations, and traffic loads. The elastomeric material maintains its resilience and sealing integrity even under dynamic conditions, ensuring long-term performance and reliability.

- Chemical Resistance: Concrete pipe seals exhibit excellent resistance to a wide range of chemicals found in wastewater and drainage systems, including acids, alkalis, and hydrocarbons. This chemical resistance prevents degradation and ensures the longevity of the seals in aggressive environments.

- Weather Resistance: Concrete pipe seals are designed to withstand exposure to UV radiation, extreme temperatures, and weathering without compromising their sealing performance. This weather resistance makes them suitable for both underground and above-ground applications in various climatic conditions.

- Flexibility and Conformability: Concrete pipe seals are highly flexible and conformable, allowing them to adapt to irregularities and variations in the pipe joints. This flexibility ensures a snug fit and uniform compression, resulting in effective sealing across the entire joint interface.

- Easy Installation: Concrete pipe seals are designed for easy installation, allowing for quick and efficient assembly of concrete pipe sections. They can be installed manually or with the aid of installation tools, minimizing labor costs and construction time.

- Durability and Longevity: Concrete pipe seals are engineered for durability and longevity, with a service life of several decades under normal operating conditions. The robust construction and resilient properties of the elastomeric material ensure reliable sealing performance over the entire lifecycle of the drainage system.

- Maintenance-Free: Concrete pipe seals require minimal maintenance once installed, reducing the need for costly and disruptive repair work. Their inherent durability and resistance to wear ensure trouble-free operation and extended service intervals, contributing to the overall cost-effectiveness of the drainage infrastructure.

In summary, concrete pipe gaskets are indispensable components in underground drainage and sewer systems, providing a reliable and durable solution for sealing joints between concrete pipes. With their excellent sealing properties, durability, flexibility, and ease of installation, concrete pipe seals contribute to the integrity, efficiency, and longevity of drainage infrastructure projects around the world.